![]() Download pdf to read later, or see below:

Download pdf to read later, or see below:

B Approved Document B – Fire Resistance

E Approved Document E – Acoustic Performance

L Approved Document L – Thermal Performance

- High Quality MDF faces (6mm)

- Lightweight / tri-layer solid timber core

- Comprehensive approvals for 30 minute fire resistance

Construction Specification:

The core of PRO LITE MDF comprises a tri-layer low density hardwood construction. The core is faced with 6mm MDF.

Size Adjustment:

Leaves may be reduced in height and width without restriction but the top rail must remain unaltered – vertical edges must be lipped in accordance with the instructions below (please refer to door edge lippings section). Single leaves up to 2260mm in height and up to 968mm in width may have the top rail removed but all edges must be lipped.

Glazing:

Up to 0.91 m2 of glazing per leaf is approved in Sentry PRO LITE MDF (all configurations). Apertures must not be less than 100mm from any door edge. Multiple apertures are acceptable up to the maximum approved total area, with a minimum dimension of 80mm between apertures. The aperture shape is not restricted, providing the intumescent material and beads are proven to be compatible with that shape.

Approved glasses are:

6/7mm Pyroshield, 7mm Pyrobelite, 7.2mm Pyroguard, 7.5 Pyrodur Plus, 10mm Pyrodur, 12mm Pyrobel, 15mm Pyrostop. Alternative glass products may be used, providing relevant evidence generated in suitable timber door construction can be provided.

Approved proprietary glazing systems are:

Lorient System 36, Sealmaster Fireglaze 30, ISL Therm-A-Glaze 30, Mann McGowan Pyroglaze 30, Reddiplex R8193 glazing channel, Lorient Flexible Figure 1. Installation must be in accordance with the glass / glazing system manufacturer’s recommendations.

Door frames:

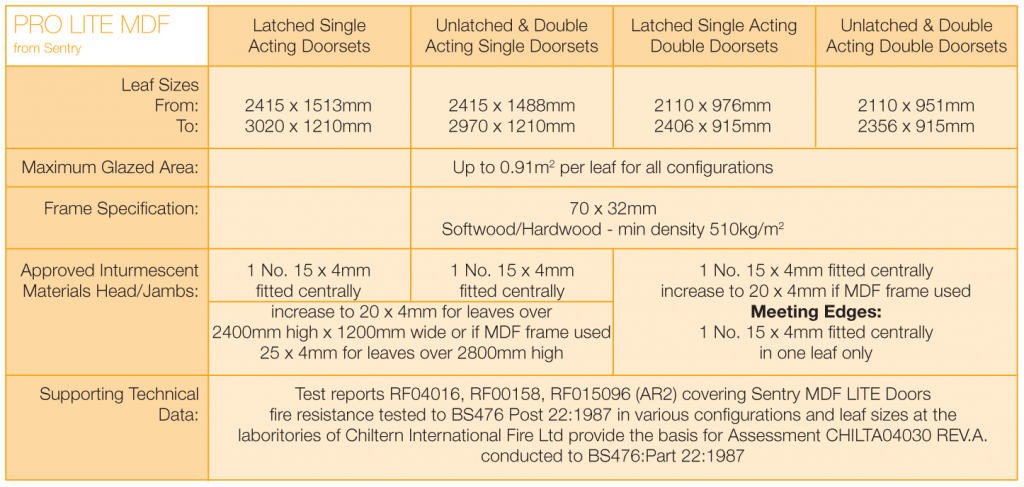

Softwood or hardwood is approved in minimum density 510 kg/m3 in a minimum section of 70 x 32 mm after rebating / profiling. Single acting door frames must incorporate a 12 mm rebated or planted stop. Double acting frames must be scalloped or fitted with shoulders to maintain specified gap dimensions. Frame joints must be morticed and tenoned, nailed or screwed and with no gaps. MDF doorframes are also approved. Please refer to the global assessment for details.

U Value:

The thermal performance of Sentry PRO LITE MDF evaluate with softwood door frame section 70 x 32, in flush door format, in accordance with B.S.EN ISO 10077-2: 2003, performed in an Approved Document L compliant configuration is:- 2.0W/m2K Report Reference Chiltern Dynamics Chilt/T04005 refers.

Intumescent materials:

ISL Therm-a-seal intumescent is approved in sections to correspond to required leaf sizes and configurations as shown in the table below. Note that intumescent seals may be fitted to the door edges or frames.

Door edge lippings:

6mm – 18mm square or 8 – 20mm rounded (maximum 2mm profiling) hardwood (minimum density 640 kg/m3) are required to vertical edges only. In areas of high humidity, all edges should be lipped. Glue lines should be UF, Cascamite or P.U. adhesives.

Overpanels:

Overpanels are permitted in all approved configurations providing they incorporate a transom of a minimum specification to that stated for door frames.

Installation Instructions:

Guidance for various methods of sealing the frame to structural opening gap is given in BS 8214:2008, code of practice for Timber Fire Door Assemblies.

If you are required to cut down the overall size of the door, it is important that any reduction in leaf height is done from the bottom of the leaf so as to retain the top rail.

Lip all edges H/W using an appropriate glue line.

Three hinges should be fitted for all exterior doors, doors weighing over 20kg and interior doors where opposing sides are exposed to extreme variations in temperature and humidity, such as bathrooms and airing cupboards.

Glazed panels in doors must comply with the requirements observed for safety glass.

Glazing beads must be correctly fitted using approved compound or glazing tapes to both sides of the glass. Approved material must be used for fire doors.

Door Gaps: It is essential that door gaps between leaf edges and the door frame and between leaves at the meeting edge/overpanel junction in double leaves are a minimum of 2mm and a maximum of 4mm. Note: The leaf contains identical top and bottom rails so it is important to identify the top of the leaf prior to trimming the leaf height and lipping. NB: Ensure correct compliant Ironmongery and glazing systems when using in a fire door application.